Why Tungsten Is Used In Light Bulb Filaments

Back in 1879, Thomas Edison created the first electric light bulb, also known as the incandescent light bulb. This bulb makes use of a tungsten filament which is the main light-producing component in the bulb.

There are a few reasons why this became the material of choice for these bulbs.

The main reasons why tungsten is used in light bulbs is because it has a high melting point, high electrical resistivity and is far more durable than any other available option. These properties make it suitable since the filament needs to be able to handle enough heat to glow but also not break in the process.

In this following article, we will go over all the major factors in depth that enabled tungsten to become the main component in one of the most important inventions of recent times.

Tungsten Has a High Melting Point

One good reason for tungsten to be used in the incandescent light bulb is that it has a very high melting point.

The melting point for tungsten is around 3400 °C (~6200 °F), which is far greater than the actual temperature a bulb actually reaches. This also makes tungsten the metal with the highest melting point.

An incandescent bulb usually peaks in heat once it reaches temperatures of around 260 °C (500 °F). However, that temperature is taken from the glass bulb surrounding the glowing filament. The filament in itself reaches temperatures of around 2500 °C (4600 °F).

It needs to reach temperatures this high because otherwise, it won’t produce white light, the type of light we can perceive.

This is a major reason why tungsten is used because in order to create a bulb using the principle of heating something up, we obviously need something that can withstand those temperatures.

However it isn’t enough that it only withstands it for single use, it needs to be able to last for a longer period of time in order to be sustainable, which many other metals simply cannot do. If you’re interested in how hot other commonly used bulbs get you can check out our article on that here.

Tungsten Has a High Electrical Resistivity

Another reason why tungsten makes for a good light bulb filament is the fact that it has a rather high electrical resistivity.

Electrical resistivity means more or less how resistant it is to an electrical current. If a material has a low resistivity it means that electrons have an easier time passing through it. In contrast, if a material has a high resistivity it is significantly harder for the electrons to pass through.

In most applications, it is good for materials to have a low resistivity, because that way we can have larger electrical currents passing through them with the same volume of material used.

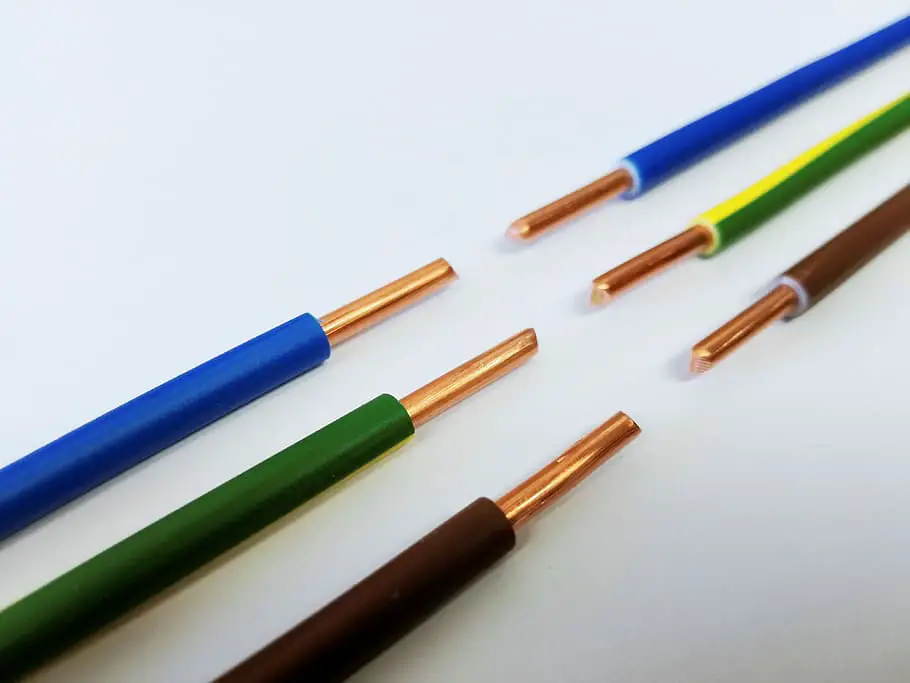

It is for this reason that copper is the material most commonly used for electrical wiring. It has a rather low resistivity and is somewhat cheap in comparison to other good conductors such as gold or silver.

However, there are applications such as this where a high resistivity is more favourable. In most of those scenarios, it is because one needs to reach a certain resistance in a circuit in order to have the desired electrical current going through that circuit. But when it comes to this application, it is a little bit different.

How High Electrical Resistivity Is Used In Light Bulbs

In order to understand this better we first need to look into what happens when a lot of electrons pass through a material.

When electrons move from point A to point B in the material there will be a slight heat generation. You can think of it in the same way as how movement generates heat in physics.

That being said, this effect gets amplified the more electrons we pass through it. This is both because of the fact that it generates more movement within the material, but also because the electrons themselves will eventually start to fight over physical space.

You can imagine this in the same way that 100 people would have to fit through one singular door. With too many electrons present they will simply start fighting for space.

This is also why the area of a conductor becomes important because the larger the area is the fewer electrons would need to fight. This is the equivalent of adding wider or more doors into the 100-people analogy.

With that being said, the more resistance given to the electrons the more they have to work to get through the material. The higher resistance also causes heat generation to increase.

Once we understand this we can begin to understand how the tungsten filament starts to glow in a light bulb.

The actual thread that is the filament is extremely thin, which acts as a very narrow pathway that the electrons have to pass through. This creates a lot of resistance within the filament, which then causes a buildup of heat and eventually a glow that emits light.

Like previously mentioned, in order for this glow to take place we need to reach very high temperatures. This is why tungsten is excellent for this purpose, because of its ability to not melt at the temperatures required for the glow.

Tungsten Evaporates Slowly

When creating something that runs at temperatures this high, you start to run into problems with things evaporating. While tungsten has a very high tolerance for high temperatures, it can cause damage to the filament on a microscopical level.

It might not sound very important if the change happens on that small of a scale, but it starts to add up when it happens often considering that the filament isn’t very large to begin with.

The way the damage is caused is because the tungsten will start to vibrate due to the electrons passing through. These vibrations can cause individual atoms to split from the rest of the filament and end up on the glass of the bulb.

Not only does this make the filament weaker due to it losing mass, but it will also start to have an impact on the light output of the bulb since there will then be a small layer of tungsten throughout the entire inside of the glass bulb.

The way they went about solving this problem was to start putting in an inert gas into the bulb. Before this they used to make the inside of the bulb a vacuum in order to prevent any sort of combustion between the immense heat and oxygen.

They did this because combustion can’t happen in the bulb if there is no oxygen present, therefore they decided that a vacuum would work to prevent this.

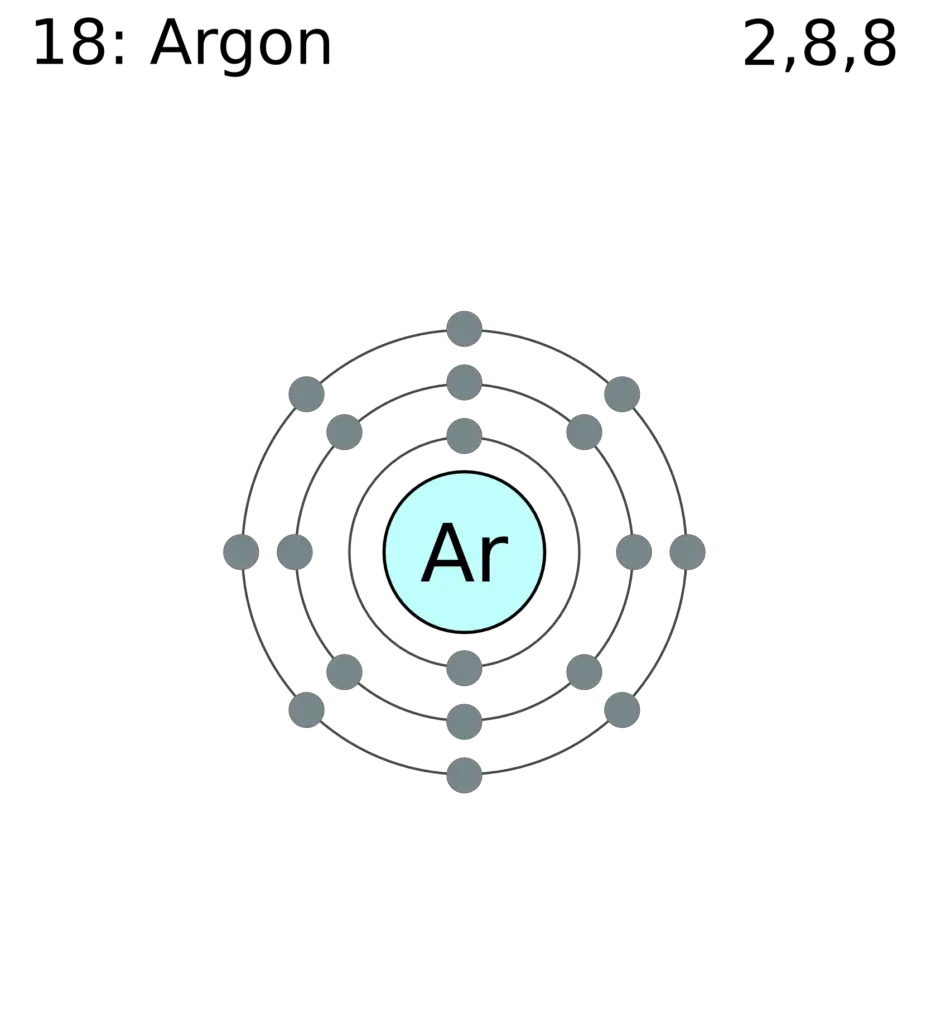

However, it is also possible to put gases into the bulb, but it is important to be careful of which gas you choose for this. Most gases would also end up in a combustion just like oxygen would, which is why an inert gas has to be used instead.

Inert gases won’t chemically react to the heat by the nature of these types of gases, which is why it was decided that they would make use of a gas like this inside of the bulb. The gas most commonly used in these bulbs is argon.

The effect of filling the bulb with glass is rather simple but very effective. What it does is that it gives the detaching tungsten atoms something to bounce off of, instead of just shooting straight out into the glass bulb.

If we give the tungsten something to bounce off of, chances are that it will bounce back into the filament again. This would cause the atom to combine with the filament again and continue to work like it did before.

Other Suitable Materials For Light Bulb Filament

After seeing some of the properties of the material used in this you might begin to wonder if there are other viable options for a bulb filament like this.

There have in fact been a few others that were contenders of being the bulb filament. There was a fair amount of trial and error with other materials before finding that tungsten was the best option.

Some of the materials used were iridium, molybdenum, chromium, carbonized paper and many more. Most of the materials tested were simply not good enough for the task at hand though.

The vast majority of the materials tested got dismissed for at least one of the following reasons:

The lifespan is too short. In order for the filament to be any useful the material needs to be able to last longer than just a few seconds, which most materials can’t handle under the present heat conditions.

The material is too fragile. The filament requires a material that won’t suffer severe damage upon regular usage.

The material is not performing good enough. Some of the materials simply didn’t produce enough light, which made them a non-optimal choice for the filament.

Material cost. In order to mass produce the bulbs you need a material that isn’t overly expensive.

There was however one viable candidate material for the filament that ended up being used for a short period of time, that material being tantalum.

Tantalum is a metal that has a very high melting point much like tungsten. Tantalum’s melting point is around 3000 °C (~5400 °F) which makes it possible for it to survive the high temperatures required to glow.

While it seems promising for tantalum, it simply was too fragile to be used effectively in a filament like this. The electrical current that would flow through the tantalum would cause too much structural damage to it, deeming it not viable after more extensive testing.

Eventually, though it was found that tungsten was just simply more effective than any other metal, making all of its competition obsolete in comparison.

Summary

To summarize, tungsten is the material of choice for light bulbs for over a century at this point. The main reasons for tungstens wide use in light bulbs are:

- That tungsten melting point is very high compared to most other materials.

- Tungsten has a high electrical resistivity.

- How tungsten doesn’t evaporate much despite the immense stress it’s put through.